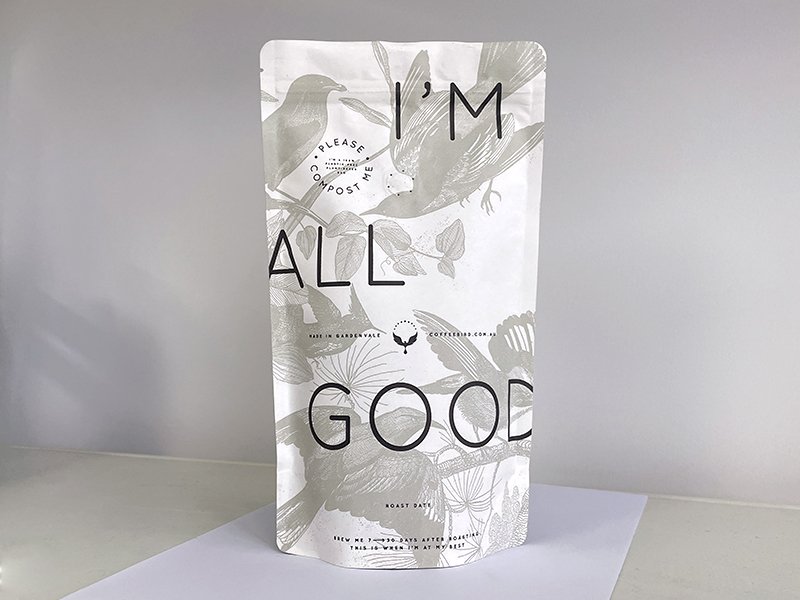

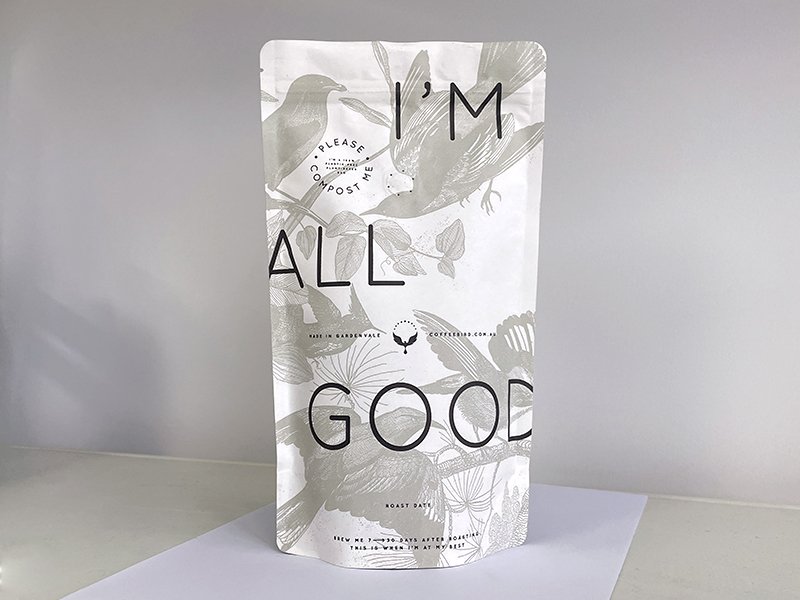

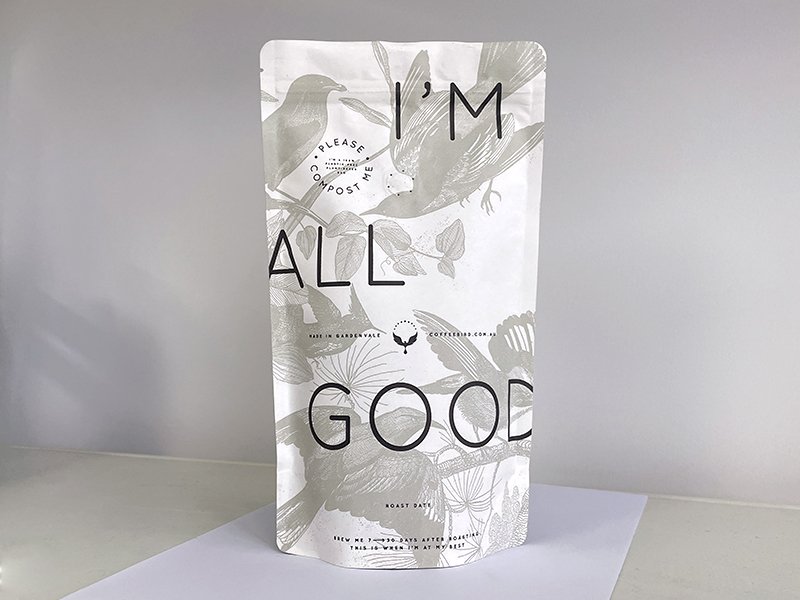

Biodegradable Coffee packaging bag is also made of compostable materials, which can complete biodegradation in 180 days or less under composting conditions, without causing harm to the environment.

In addition to the responsibility and obligation to the earth, choosing biodegradable coffee bags can get more people’s attention and greatly increase the customer’s favorable impression of your brand.

And according to the report, 65% of people are now concerned about biodegradable packaging, especially young people, who are more willing to pay a premium for products that are environmentally friendly.

In addition to the responsibility and obligation to the earth, choosing biodegradable coffee bags can get more people’s attention and greatly increase the customer’s favorable impression of your brand.

And according to the report, 65% of people are now concerned about biodegradable packaging, especially young people, who are more willing to pay a premium for products that are environmentally friendly.

PLA: is the most common inner layer material in biodegradable coffee packaging bags, with good mechanical properties, physical properties and thermal stability. Suitable for blow molding, thermoplastic and other processing methods.

The CO₂ generated during the decomposition process will be directly absorbed and utilized by plants, and will not be discharged into the air and will not produce a greenhouse effect.

PBS: The source of synthetic raw materials can be either petroleum or biological. Excellent mechanical properties, good heat resistance, thermal deformation temperature close to 100 ℃.

PBS and PLA can also be used as printing layer

PLA: is the most common inner layer material in biodegradable coffee packaging bags, with good mechanical properties, physical properties and thermal stability. Suitable for blow molding, thermoplastic and other processing methods.

The CO₂ generated during the decomposition process will be directly absorbed and utilized by plants, and will not be discharged into the air and will not produce a greenhouse effect.

PBS: The source of synthetic raw materials can be either petroleum or biological. Excellent mechanical properties, good heat resistance, thermal deformation temperature close to 100 ℃.

PBS and PLA can also be used as printing layer

Biodegradable materials that can be used as insulating layers are: NKME and kraft paper.

NKME: With metallic luster, excellent strength and barrier properties, it is a common material for the production of biodegradable custom coffee packaging bags

Kraft paper: As one of the traditional materials for making flexible packaging, kraft paper has very good degradability and barrier properties, Can be directly used as printing layer

Biodegradable materials that can be used as insulating layers are: NKME and kraft paper.

NKME: With metallic luster, excellent strength and barrier properties, it is a common material for the production of biodegradable custom coffee packaging bags

Kraft paper: As one of the traditional materials for making flexible packaging, kraft paper has very good degradability and barrier properties, Can be directly used as printing layer

The valves and zippers we provide are 100% biodegradable. Your guests will no longer need to cut the pull and air valve after use. It not only achieves the best environmental protection effect, but also saves the trouble of your guests, and enhances the guests’ favorability of the brand from the details.

The valves and zippers we provide are 100% biodegradable. Your guests will no longer need to cut the pull and air valve after use. It not only achieves the best environmental protection effect, but also saves the trouble of your guests, and enhances the guests’ favorability of the brand from the details.

Material combination: PLA + NKME + PBS

Insulation layer: NKME, the insulation of NKME is at the top level among biodegradable materials, which can well guarantee the taste of coffee beans.

Printing layer: transparent PBS. Due to the excellent properties of PBS, it can be waterproof and 9-color printing as a printing layer. But PBS also has a disadvantage, the MOQ is up to 50,000.

MOQ:50,000, because there is PBS, the MOQ is 50,000.

Material combination: PLA + NKME + PBS

Insulation layer: NKME, the insulation of NKME is at the top level among biodegradable materials, which can well guarantee the taste of coffee beans.

Printing layer: transparent PBS. Due to the excellent properties of PBS, it can be waterproof and 9-color printing as a printing layer. But PBS also has a disadvantage, the MOQ is up to 500.

MOQ:500, because there is PBS, the MOQ is 500.

Material combination: PLA + Kraft Paper

Inner layer: PLA with high cost performance and good thermoplasticity is used as the heat sealing layer, which is 100% degradable.

Outer layer: The insulation is slightly inferior to NKME, and it also has a very good protective effect on the taste of coffee beans. At the same time, your design can also be directly printed on kraft paper, which can complete 5-color printing. ((If you want more color designs, you can consider adding PBS to the kraft paper, the MOQ will become 50,000))

MOQ: 5000.

Material combination: PLA + Kraft Paper

Inner layer: PLA with high cost performance and good thermoplasticity is used as the heat sealing layer, which is 100% degradable.

Outer layer: The insulation is slightly inferior to NKME, and it also has a very good protective effect on the taste of coffee beans. At the same time, your design can also be directly printed on kraft paper, which can complete 5-color printing. ((If you want more color designs, you can consider adding PBS to the kraft paper, the MOQ will become 500))

MOQ: 500.

Material combination: PLA + NKME + Kraft Paper

Inner layer: Milky white PLA

Outer layer: NKME and kraft paper together form the insulating layer. The best isolation effect, as a coffee bag, can protect the taste of coffee beans to the greatest extent. Kraft paper as the outermost layer can achieve up to 4-color printing. (If you want more color designs, you can consider adding PBS to the kraft paper, the MOQ will become 50,000)

MOQ: 20,000.

Material combination: PLA + NKME + Kraft Paper

Inner layer: Milky white PLA

Outer layer: NKME and kraft paper together form the insulating layer. The best isolation effect, as a coffee bag, can protect the taste of coffee beans to the greatest extent. Kraft paper as the outermost layer can achieve up to 4-color printing. (If you want more color designs, you can consider adding PBS to the kraft paper, the MOQ will become 500)

MOQ: 500.

Customers: Small and medium coffee maker.

Demand: The customer wants a coffee bag that is biodegradable and has good insulation.

Quantity: 5000

Material: PLA+Kraft Paper

Because the number of customized coffee bags required by the guests is not large, PLA and kraft paper are recommended to the guests;

Since the customer’s design does not exceed 5 colors, it is suggested that the customer can directly print the design on the kraft paper without adding PLA as a printing layer, which will save costs.

The printing process chooses flexographic printing to ensure the printing effect as much as possible.

Customers: Small and medium coffee maker.

Demand: The customer wants a coffee bag that is biodegradable and has good insulation.

Quantity: 500

Material: PLA+Kraft Paper

Because the number of customized coffee bags required by the guests is not large, PLA and kraft paper are recommended to the guests;

Since the customer’s design does not exceed 5 colors, it is suggested that the customer can directly print the design on the kraft paper without adding PLA as a printing layer, which will save costs.

The printing process chooses flexographic printing to ensure the printing effect as much as possible.

We provide PLA, PBS, NKME, Kraft Paper, as well as air valves and zippers, all of which have obtained corresponding certifications. You can choose us with confidence to customize your coffee bags.