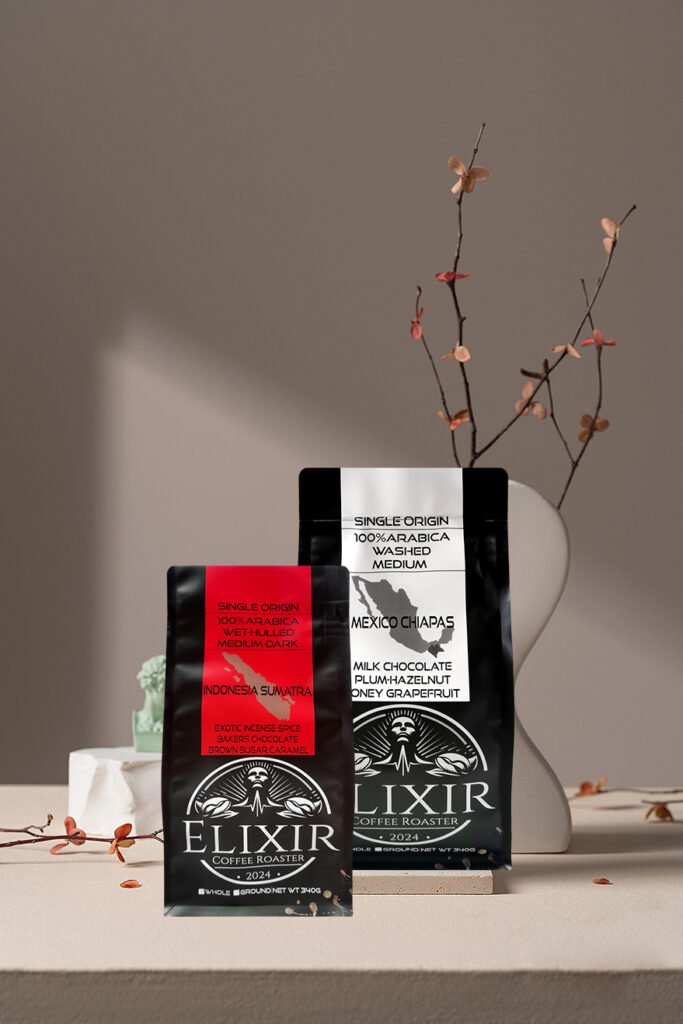

Have you poured countless efforts into carefully selecting green beans and meticulously roasting them, all to perfectly deliver that pinnacle flavor to your customers? But have you ever considered that an inconspicuous packaging bag might undo all that hard work?

The journey of coffee beans from your roastery to the consumer is fraught with flavor killers: oxygen, moisture, and light. And the coffee bag is the only guardian on this journey.” As a professional coffee packaging solutions provider, we understand that a high-quality coffee bag is not just a container, but also an extension of your brand reputation and a guarantee of quality.

1.The “Enemies” of Coffee Beans and the “Hidden Costs” for Roasters

1.1 Oxygen—The Number One Killer of Flavor

Impact on Flavor: Causes oxidation, producing rancid and stale flavors, and causing delicate flavors such as floral and fruity notes to dissipate rapidly.

Costs for Roasters: Customer complaints, product returns, damage to brand reputation—”Why is the coffee I bought from you not as good as the coffee I drank in the store?”

1.2 Moisture and Heat – Accelerators of Quality

Impact on Quality: Accelerates spoilage, increases the risk of mold, and renders coffee beans lifeless.

Costs for Roasters: Shortens shelf life, limits sales radius, and impacts inventory safety.

1.3 Light – The Invisible Destroyer

Impact on Quality: Ultraviolet light directly damages coffee oils and aromatic molecules.

Costs for Roasters: Even if the beans are fresh, their flavor will be significantly diminished after just a few days on the shelf.

“When customers don’t repurchase due to poor flavor, they rarely blame the packaging; ultimately, it’s your brand, the roaster, that suffers.”

2.Four Essential Protective Characteristics of a Professional Coffee Bag

2.1 The Ultimate Barrier: High-Barrier Materials

When we call a coffee bag a “guardian,” its core lies in the materials it uses. A professional coffee bag is far more than just a single layer of plastic; it’s like a precision “armor” tailored specifically for coffee beans, employing a multi-layered composite structure (such as the classic PET/AL/PE structure) to work together and comprehensively resist external aggressors.

In the packaging industry, we don’t judge quality based on intuition alone, but on scientific data. Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR) are two of the most critical “report cards” for measuring packaging barrier performance. Ordinary single-layer plastic packaging (such as PP or PE bags) has very high OTR and WVTR values, meaning oxygen and water vapor can enter and exit relatively freely, offering virtually no protection for coffee flavor. Our multi-layered composite structure with aluminum foil (AL) reduces these two key indicators to extremely low levels (e.g., OTR can approach or even reach 0). (cm³/m²·24h). Our products not only far surpass ordinary plastic bags in barrier performance, but also reach a leading level in the industry.

2.2 The Wisdom of Breathing: Precise One-Way Exhaust Valve

If the exhaust rate is too low, the rapidly generated CO₂ cannot be expelled in time, causing the packaging to bulge severely in the first few days after production, even bursting. This leads to storage and transportation problems and gives consumers a poor impression of quality.

Our exhaust valve is precision-engineered with an optimized exhaust rate. Like an experienced sound engineer, it smoothly and promptly removes CO₂ from the bag, effectively preventing the embarrassing bulging of the packaging and maintaining its crisp and professional appearance.

Inferior exhaust valves, after expelling CO₂, may not have a perfectly repositioned diaphragm for sealing, or the valve itself may have poor sealing, allowing trace amounts of oxygen to continuously seep back into the bag. This is a “silent killer,” quietly ruining the coffee flavor every day.

The core of our exhaust valve lies in its superior anti-oxygen backflow performance. It uses high-quality precision components and a special diaphragm to ensure near-absolute sealing when the gap in CO₂ discharge and the internal and external pressure are balanced, effectively preventing external oxygen from seeping back in.

2.3 The Art of Sealing: Robust and Reliable Sealing Systems

The sealing of coffee bags is the point where consumers interact most frequently with your product. It’s not only the last physical line of defense for freshness, but also a key touchpoint influencing the user experience. A seal that’s difficult to seal or easily damaged will directly cause customers to doubt the quality of your brand. We understand this well, and therefore offer you a variety of professional and reliable sealing solutions to suit different coffee bean usage scenarios and consumption habits.

High-Strength Resealable Zippers: We don’t use ordinary, fragile zippers, but rather widened and thickened engineering plastic zippers. Their locking structure has been optimized to provide a clear “click” closure. Ensure a tight seal.

Easy-tear precision heat seal: This thin seal is a testament to our technological prowess. Through precise heat sealing control, we achieve uniform peel strength.

2.4 Brand Armor: Customized Design and Materials

We offer full-color printing, matte/gloss finishes, and custom sizes and shapes. Packaging is your first interaction with your customers. High-quality, well-designed packaging instantly elevates your brand image and makes your products stand out on the shelf.

We understand that every baker has unique needs and budgets, and we are happy to provide you with free packaging consultations and samples. Please tell us your requirements.